Crownwell Oil-injected Permanent Magnet Variable Speed Screw Air Compressor – CWD355A-PM-10

Motor Power: 355 kW

Max. Capacity: 1995 cfm

Max. Working Pressure: 10 bar

Air Compressor

Technical specification

| Type |

|

Oil-injected Permanent Magnet Variable Speed Screw Air Compressor |

| Model |

|

CWD355A-PM-10 |

| Max. Capacity |

cfm |

1995 |

| Max. Working Pressure |

Bar |

10 |

| Motor Nominal Power |

kW |

355 |

| Driving Mode |

|

Direct driven |

| Cooling Method |

|

Water-cooled |

| Max Environment Temp. |

℃ |

46 |

| Noise Level |

dB(A) |

84 |

| Oil Carryover |

ppm |

<3 |

| Power requirement |

V/Hz/Ph |

380/50/3 |

| Connection |

|

DN100 |

| Outline dimension (L/W/H) |

mm |

3980/2260/2460 |

| Weight |

Kg |

7800 |

| Screw Compressors- We call “PANTHER” |

| Crownwell offer a range of robust industrial rotary screw air compressors with pressure from 7 to 13bar and power from 5.5 to 400KW. Like all Crownwell compressors, Panther is backed-up by a group of senior engineers with more than thirty years design experience. Crownwell offers the industries most reliable and cost competitive compressed air packages. Each component has been thoroughly evaluated for its reliability and high-efficiency and optimized for easy maintenance. |

|

| PM: Permanent Magnet, DRIVING DOWN ENERGY COSTS |

| Environment friendly, Energy Saving Star Over 80% of a compressor’s lifecycle cost is taken up by the energy it consumes. Moreover, the generation of compressed air can account for more than 40% of a plant’s total electricity bill. To drive down your energy costs, Crownwell pioneers Permanent Magnet (PM) technologies in the compressed air industry. Permanent Magnet motor and inverter lead to major energy savings, while protecting the environment for future generations. Crownwell offers a wide range of integrated PM compressors in the market.

|

|

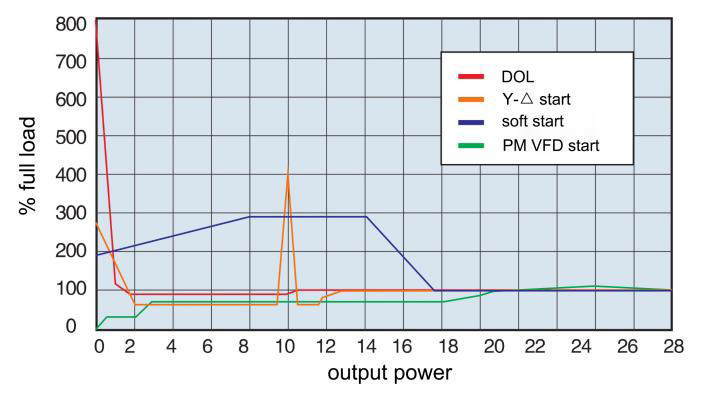

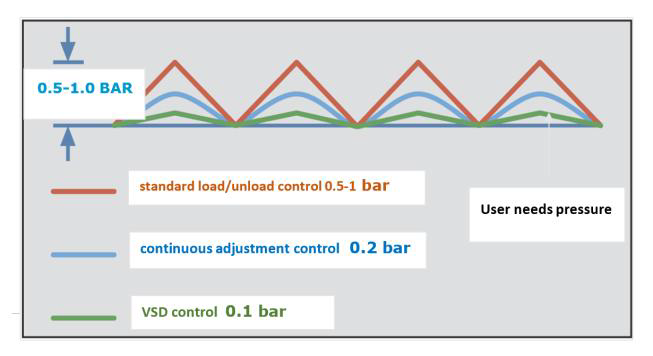

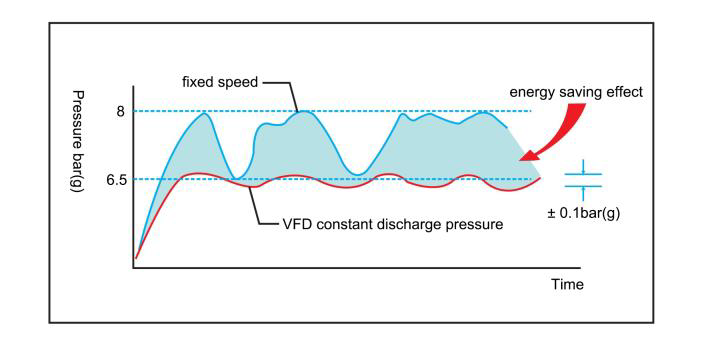

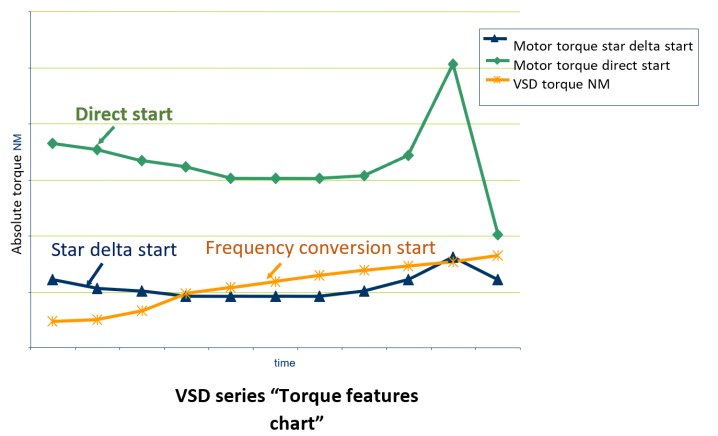

| Crownwell develops its variable speed screw compressors to be high energy efficiency. At full load, the variable speed compressors will produce the most air using the least energy. Even more important, Crownwell will guarantee these efficiencies down to loads as low as 25%. A conventional, fixed-speed air compressor is controlled by a suction control valve that modulates between open and closed positions. But using the suction valve to meet system air demand results in extreme pressure fluctuations and wasted energy, greatly reducing efficiency whenever the compressor operates outside its optimum performance range. Using a frequency inverter, Crownwell compressors deliver the only true variable speed drive. With a true VSD, air is delivered at a constant pressure, regardless of demand, at maximum efficiency. Remarkably, Crownwell compressors achieve constant pressure and maximum efficiency across their entire operating range, from 100% loaded down to as low as 25% loaded. High quality inverter equipped in PM series contributing to energy saving purpose.

|

|

| Air end |

| Rotor is the key element in producing compressed air efficiently. Crownwell airends utilize a 5-lobe male rotor (driving rotor) and a 6-lobe female rotor (driven rotor) which are the top class and new generation. Crownwell core guarantees you superior FAD efficiency, more robustness and reliability. Larger rotors are designed to

ensure slower rotor speed of airends to deliver compressed air more efficiently than small airends. It contributes to energy cost savings and a longer lifespan. Oversized SKF bearings and triple discharge end bearing design offers long operating life.

|

|

| PM Motor & Direct Coupling |

| Permanent Magnet variable speed compressor is equipped with high efficiency permanent Magnet motor. PM motor is more efficient than induction motor. High-efficiency IEC motors are adopted. Over sized cast iron conduit boxes make connections easy. The best grease is used to protect the SKF bearings. High performance and low temperature rise. The latest Germany designed spider couplings are used to guarantee the reliability and driving efficiency and provide vibration free power driving for quiet and maintenance free operation.

|

|

| Suction Valve |

| Suction valve is the major air flow control component. It controls air flow to the compressor either by opening, throttling, or closing completely in response to pressure sensor controls. High quality& high reliable.

|

|

| Oil Separation System |

| The three-stage separation system supplies high quality compressed air. Oil separator adopts tangential intake, there is a oil baffle between inner wall and apron to pre filter lubricant, then the oil-air mixture flow out through oil separator from inside to outside. The separation tank has two different separation stages: centrifugal and gravity. The third stage separation is provided by a high performance, long life coalescent separator filter. The efficiency of the first two stages assures the long lifespan of this coalescent filter. This system limits oil vapors carryover to below 3ppm.

|

|

| Oil Filter |

| Featured with large filtering covering and high preciseness. It effectively filters the remains of the worn flying parts and the impurities in the oil, which makes lubricant circularly injected into rotor and bearing filtered clean, and guarantees much longer lifespan of the compressor.

|

|

| Air Filter |

| 99.99% high efficiency, low pressure loss, high quality air filter provides filtration to less than 3microns utilizing ultra web nanofiber technology which ensures clean, unrestricted air flow for optimal compressor operation. It controls the suction air quality and guarantee the compressor can work in a heavy dust and complex working environment. |

|

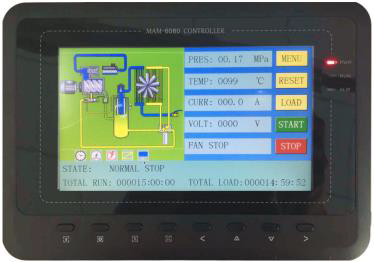

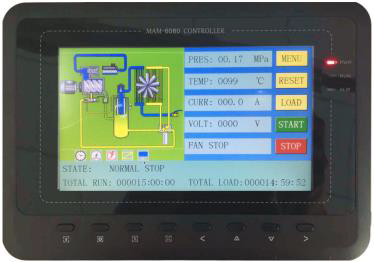

| Control System |

| Full control in a few clicks. Crownwell LCD controller gives you easy access to menus and all key performance indicators necessary to drive your operation. It also features remote control interface RS485 (optional) with up to 4 compressors, programmed routine maintenance, fault log, recording of running history, warning and stop alarms, and several other functions. All microprocessor functions are password protected, accessible only by authorized personnel.

Schneider/CHNT electrical components are adopted which has long lifespan and strong capability of shock resistance, to avoid damage when voltage is unstable.

|

|